Key Takeaways

- Metal roofing gauge most often comes in 22, 24, 26, and 29, with lower numbers indicating thicker and more durable options, crucial for weather resistance and longevity.

- Choosing a suitable gauge depends on building type, local climate, and budget, with thicker panels recommended for harsh conditions and environments demanding reinforced structural integrity.

- Thicker gauge panels offer enhanced weather resistance and durability, while thinner panels can be cost-effective for mild climates and less demanding applications.

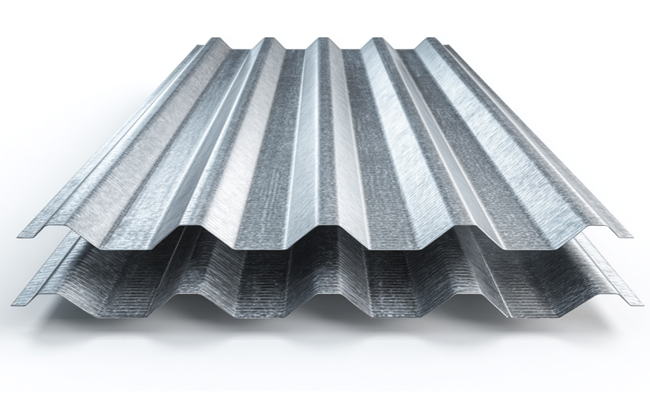

Understanding Metal Roofing Gauge

A metal roofing gauge indicates the thickness of the metal panel. It is an important measurement when determining the durability and quality required for a property. Key points about metal roofing gauge:

- The gauge number inversely relates to the thickness: the lower the gauge number, the thicker the metal.

- A 22-gauge metal roof is thicker than a 24-gauge roof.

- The thickness difference directly impacts the roof’s durability and performance

Thicker gauges, such as 22-gauge, offer superior durability, making them ideal for areas with harsh weather conditions. They are more resistant to damage from heavy rain, snow, and high winds. On the other hand, thinner gauges, such as 29-gauge, are less durable but can be suitable for less demanding environments.

Selecting the correct gauge has a significant impact on the roof’s ability to withstand environmental stresses, influencing both maintenance needs and overall longevity. Understanding these basics sets the foundation for making an informed choice that balances cost, durability, and performance.

Common Gauges in Metal Roofing

The most commonly used metal roofing gauges are:

- 22-gauge

- 24-gauge

- 26-gauge

- 29-gauge

22-Gauge Metal Roofing

22-gauge metal roofing is the thickest and most durable option available, with a thickness of 0.0299 inches. Its benefits include:

- Exceptional resistance to severe weather conditions, such as high winds and heavy snowfall

- Superior protection for your building

- Unparalleled durability, leading to less frequent maintenance

- Fewer repairs over time. Homeowners often choose 22-gauge metal roofing for these reasons.

While 22-gauge metal roofing can add to the overall cost, its long-term benefits justify the investment. The robustness and longevity of 22-gauge panels make them a worthwhile choice for those prioritizing durability over initial cost.

24-Gauge Metal Roofing

24-gauge metal roofing is a popular choice for both commercial and upscale residential buildings, offering a balance between cost and strength. It offers a good balance of durability and affordability, making it a popular choice for various applications. The typical cost for 24-gauge standing seam metal roofing is between $2.50 and $3.50 per square foot. This price range reflects standard market rates for this material.

Compared to 22-gauge metal roofing, 24-gauge metal roofing is thinner but still provides excellent durability. It is often used in applications where a lower gauge is not necessary, offering adequate protection in areas with moderate weather conditions.

26-Gauge Metal Roofing

26-gauge metal roofing is widely used in both residential roofing and commercial settings, thanks to its decent durability and affordability. With a thickness of 0.0188 inches, it strikes a balance between performance and cost. This gauge is particularly appealing to homeowners seeking budget-friendly solutions without severely compromising on quality.

While 26-gauge metal roofing offers reasonable durability, potential issues, such as leaks, should be considered with certain panel types. Evaluate the specific needs of your project to determine if 26-gauge metal roofing is the best choice.

29-Gauge Metal Roofing

29-gauge metal roofing is the thinnest option available, measuring 0.0142 inches in thickness. This makes it the least expensive choice among metal roofing options. Despite its thinness, 29-gauge metal roofing is commonly used in homes across the United States for applications that do not require heavy load-bearing, such as siding and decorative features.

This standard gauge is particularly suitable for smaller sections or decorative purposes, offering significant cost savings. Precautions should be taken when walking on a 29-gauge roof to avoid damage, such as stepping only on support beams.

Choosing 29-gauge metal roofing can result in overall installed cost savings.

Factors Influencing Gauge Choice

Several factors influence the choice of metal roofing gauge, including the type of building, local climate conditions, and cost considerations. These factors are crucial in determining the appropriate gauge for your specific project, ensuring the chosen metal roofing performs well under the given conditions.

Building Type and Structural Support

The type of building significantly impacts the choice of metal roofing gauge:

- Thicker panels provide better structural support in open-framed buildings, making them essential for post-frame constructions that span between trusses.

- Thicker gauge panels are typically required for heavier loads.

- Using thicker panels enhances the overall structural integrity of the building.

Consider the construction type, location, and customer priorities when selecting a gauge. Thicker metal panels are often recommended for buildings needing robust structural support. This ensures the roofing system can withstand various stresses and maintain its integrity over time.

Climate and Weather Conditions

Local climate and weather conditions are crucial in determining the appropriate metal roofing gauge. In areas with severe weather, such as high winds or heavy snowfall, using thicker gauges, like 22-gauge, provides better resistance and durability. Thicker gauges can also reduce damage risks in areas prone to hail.

For regions with a mild climate, 24-gauge or 26-gauge metal roofing can be an ideal choice, offering a good balance of durability and cost. Thicker gauges are better suited for extreme weather conditions, ensuring the roofing system can handle the stresses of harsh environments.

If you live in Florida, check out: Best Residential Metal Roofing for Florida

Cost Considerations

Cost is a significant factor when choosing a metal roofing gauge. Thicker gauges generally entail higher material cost and installation costs due to increased material usage. For instance, 22-gauge metal roofing is the most expensive option among standard gauges.

On the other hand, 26-gauge metal roofing is less expensive than 22 and 24-gauge options, making it more appealing for budget-conscious projects. The cost difference between 26-gauge and 29-gauge metal roofing can range from 10% to 20% for material costs, with 29-gauge being the cost-effective choice for non-harsh climate areas.

Measuring Metal Roofing Thickness

Accurately measuring the thickness of metal roofing ensures you select the right gauge for your project. A tape measure can be used effectively, though it might lack the precision of other tools. To measure thickness using a tape measure, first locate the measurement in millimeters and then convert it to inches by multiplying by 0.03937.

Calipers are considered one of the most accurate tools for measuring metal thickness, making them ideal for precision work. Using reliable methods to measure metal roofing thickness ensures you have the precise information needed to make informed decisions.

Comparing Gauge Options for Different Applications

Different applications require different metal roofing gauges. For residential homes, 24-gauge metal roofing is commonly accepted as the industry standard, providing a balance between weight and durability. For homes in regions with heavy snow and strong winds, a minimum gauge of 24 or heavier is recommended.

In areas prone to hail, 26-gauge metal roofing offers moderate protection. For low-end agricultural jobs where cost efficiency is a priority, 26-gauge or 29-gauge wire is typically used.

Post-frame buildings, also known as pole barns, should utilize thicker metal panels that can withstand more substantial loads.

Advantages of Thicker Gauge Panels

Thicker-gauge metal roofing panels offer numerous advantages, including:

- Higher resistance to weather-related damage, like hail and heavy rain

- Improved resistance to severe weather conditions, such as high winds and heavy snow

- Better protection against impacts, making them suitable for areas prone to hail. Additionally, metal roof panels provide enhanced durability and longevity.

A thicker metal roof can have a longer lifespan due to its enhanced structural integrity and weather resistance. Thicker gauge panels make for a more rigid metal roofing system, reducing the likelihood of bending or warping.

Overall, thicker panels enhance durability and offer more protection in roofing applications, utilizing high-quality roofing materials to provide an extra layer of security.

When to Opt for Thinner Gauge Panels

Thinner gauge panels are suitable in scenarios where cost-saving measures are prioritized, and the climate is mild. In residential construction, thinner gauge panels can be sufficient as the metal’s role is primarily to protect the underlying sheathing. Lighter gauge roofing, like 29-gauge, is often adequate in regions without extreme weather events, reducing overall costs.

The structural role of thinner panels is minimal if properly supported by structural sheathing and a weather-resistant barrier. This makes thinner gauge panels a practical choice for cost-effective roofing solutions in less demanding environments, ensuring they remain structurally sound.

Paint Systems and Their Impact on Gauge Availability

The choice of paint systems can impact the availability of different metal roofing gauges. The two primary types of paint systems for metal roofing are PVDF and SMP. PVDF coatings are more commonly specified in architectural applications due to their superior properties. However, light-gauge steel is not available with a PVDF paint finish, limiting options for thinner gauges.

Thicker-gauge materials often offer more color and finish options, thereby enhancing their aesthetic appeal. PVDF paint systems offer better color integrity and less fading compared to SMP. SMP finishes, on the other hand, can achieve textured appearances that help minimize the visual impact of imperfections in flat panels.

Read our blog post for more info and answers to Can You Paint Metal Roofing?

Installation Tips for Different Gauges

When installing metal roofing, the gauge you choose will impact the process and the required structural support. For example, 24-gauge metal roofing weighs 30 percent more than 26-gauge roofing, which can affect the structural support needed during installation. This makes it essential to ensure that the structure can handle the additional weight.

Using 24-gauge standing seam metal roofing offers the following advantages and considerations:

- Allows for concealed fasteners, enhancing the weather-tightness and longevity of the installation.

- For thinner gauges, such as 29-gauge, it’s crucial to step only on support beams to avoid damaging the panels.

- Proper handling and fastening techniques will ensure a successful installation, regardless of the gauge, including exposed fastener options.

Metal Roof Gauge Summary

Choosing the best metal roofing gauge involves understanding the relationship between gauge and thickness, as well as considering factors such as building type, climate, and cost. Thicker gauges offer superior durability and weather resistance, making them ideal for harsh environments. Thinner gauges, while less durable, can be cost-effective solutions for milder climates and non-structural applications.

By weighing these factors, you can select the right gauge for your specific needs, ensuring a durable, long-lasting metal roofing system. Whether you’re a homeowner or a contractor, this guide equips you with the knowledge to make an informed decision, balancing performance, cost, and suitability for your project.

Frequently Asked Questions

What is the difference between 22-gauge and 29-gauge metal roofing?

The primary difference between 22-gauge and 29-gauge metal roofing is thickness, with 22-gauge being thicker and more durable for severe weather conditions, while 29-gauge is lighter and more cost-effective for milder climates. Thus, your choice should depend on the environmental conditions and structural needs of your project.

Why is 24-gauge metal roofing considered the industry standard?

24-gauge metal roofing is deemed the industry standard due to its optimal balance of cost and durability, making it ideal for a variety of applications. This gauge ensures longevity and performance, meeting the needs of both commercial and high-end residential projects.

How do climate and weather conditions affect the choice of metal roofing gauge?

Thicker metal roofing gauges, such as 22-gauge, are recommended for regions facing severe weather to ensure greater durability, while milder climates can utilize thinner gauges like 26-gauge or 29-gauge for cost-effectiveness. Ultimately, your choice should align with your local climate conditions.

What tools are best for measuring metal roofing thickness?

Calipers are the best choice for accurately measuring metal roofing thickness, although a tape measure can be used effectively with some conversion.

How does the choice of paint system impact the availability of different gauges?

The choice of paint system significantly impacts gauge availability, with PVDF systems predominantly suited for thicker gauges, whereas SMP finishes cater to both thicker and thinner gauges, offering a wider variety of colors and finishes.

(352) 293-2449